- +91 98242 65650

- info@strainerfilter.in

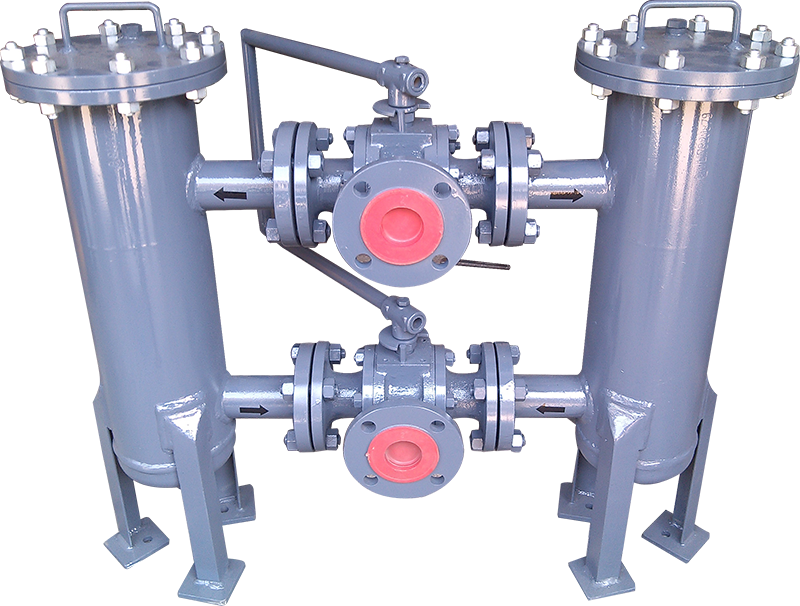

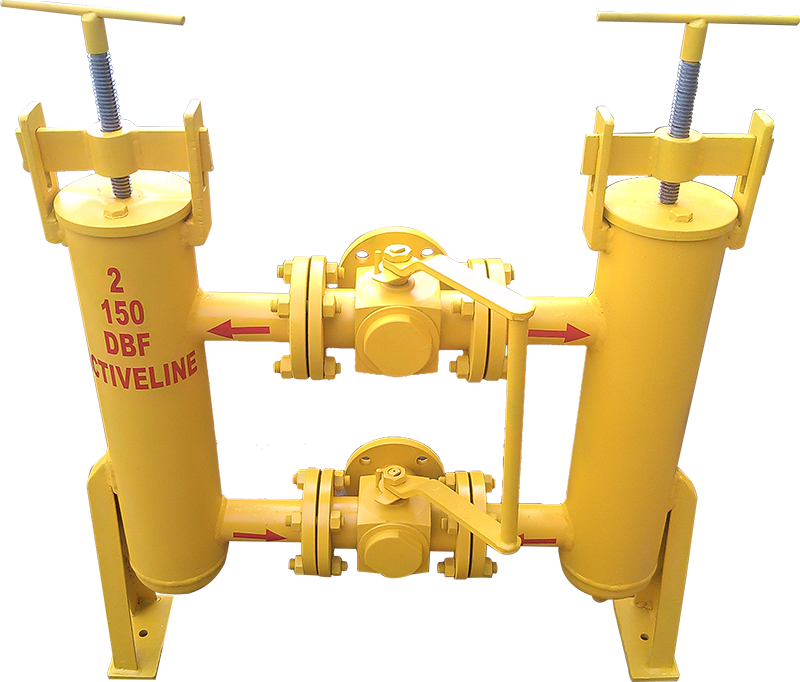

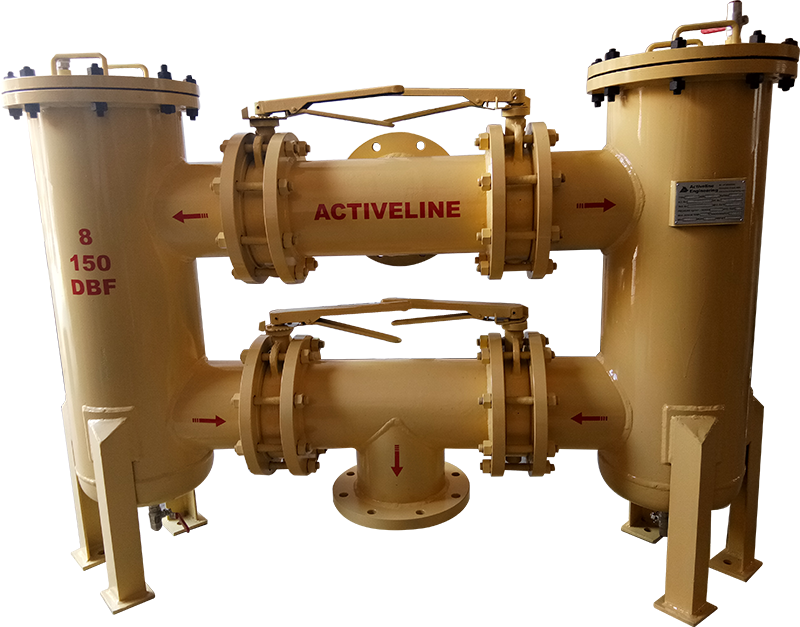

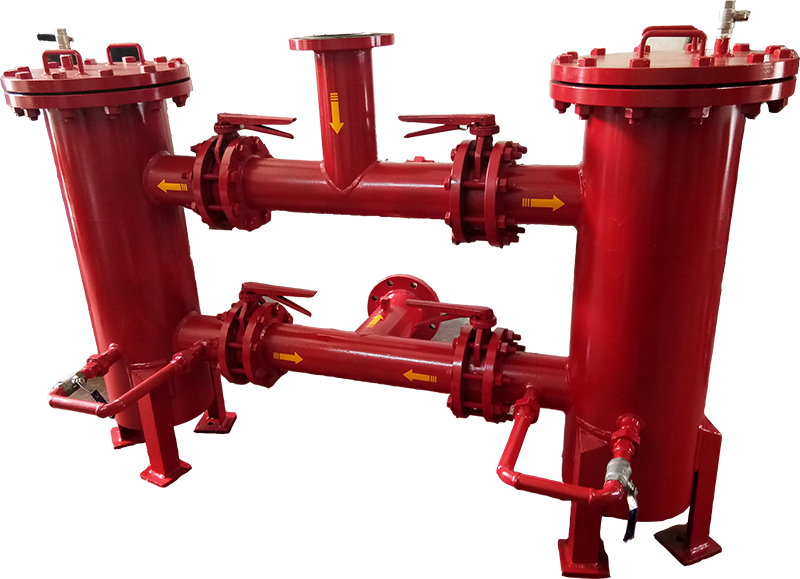

Duplex Basket Strainer / Filter

Inline / Off line Welded design Strainer, Element Basket with Mesh, Horizontal / Vertical Fitment with Flanged End / Butt Weld End – 150# to HigherActiveline Duplex Type strainers are used to clean liquid, viscous and gaseous media. They offer perfect protection against undesirable particles and are cost effective in protecting your piping, industrial valves and plants. The cleaning of the sieve inserts can be done during production. By manual or automatic switching of the filter unit does not interrupt the production process.

Applications

Filtration Of Media In Automated Production Processes, Wastewater, Protection Of Heat Exchangers, Food Industry, Lubrication Systems, Cooling Towers, Boiler Feed Water, Paper Coating, Refining, Watering Plants, Paper Industries, And Many More…

Design Features

- Protection pipe systems, Clean liquid, Viscous and Gaseous Media

- 2-way ball valves for uninterrupted production process by manual switchable filter unit.

- Variants with 3-way ball valves for compact design.

- Butterfly valves for uninterrupted production process by manual switchable filter unit.

- Extensive accessories and technical equipment.

- Large filtration area, Compact Size and Weight.

- Extensive Accessories and Technical Equipment.

- Various Surface coating and Special materials

- The Strainer basket is easily removed, cleaned and replaced without breaking the piping connection

- Changeover from a contaminated strainer basket to clean one is quick and easy, with less down time and more run time

Optional

Special Material (Monel, Hastelloy, Duplex & Other), Quick open cover without tools, Pedestal, Supporting bracket, mounted valves, Heating Jacket……

Mounted

Shut off and Regulating Media Stream :-Ball Valves, Butterfly Valves, Gate Valves, Blank Disks, Ring Spacers, Orifice Plates

Security and Monitoring of the Media :- Magnet Bars, Differential Pressure Display, Analogue / Digital Thermometers

Physical Characteristics

- Line size

- Types of piping connections (clamped, bevel seat, I-line, or other)

- Construction materials

- Gasket materials

- Required Particle, Mesh, Hole, or Slot size in the Strainer / Filter element